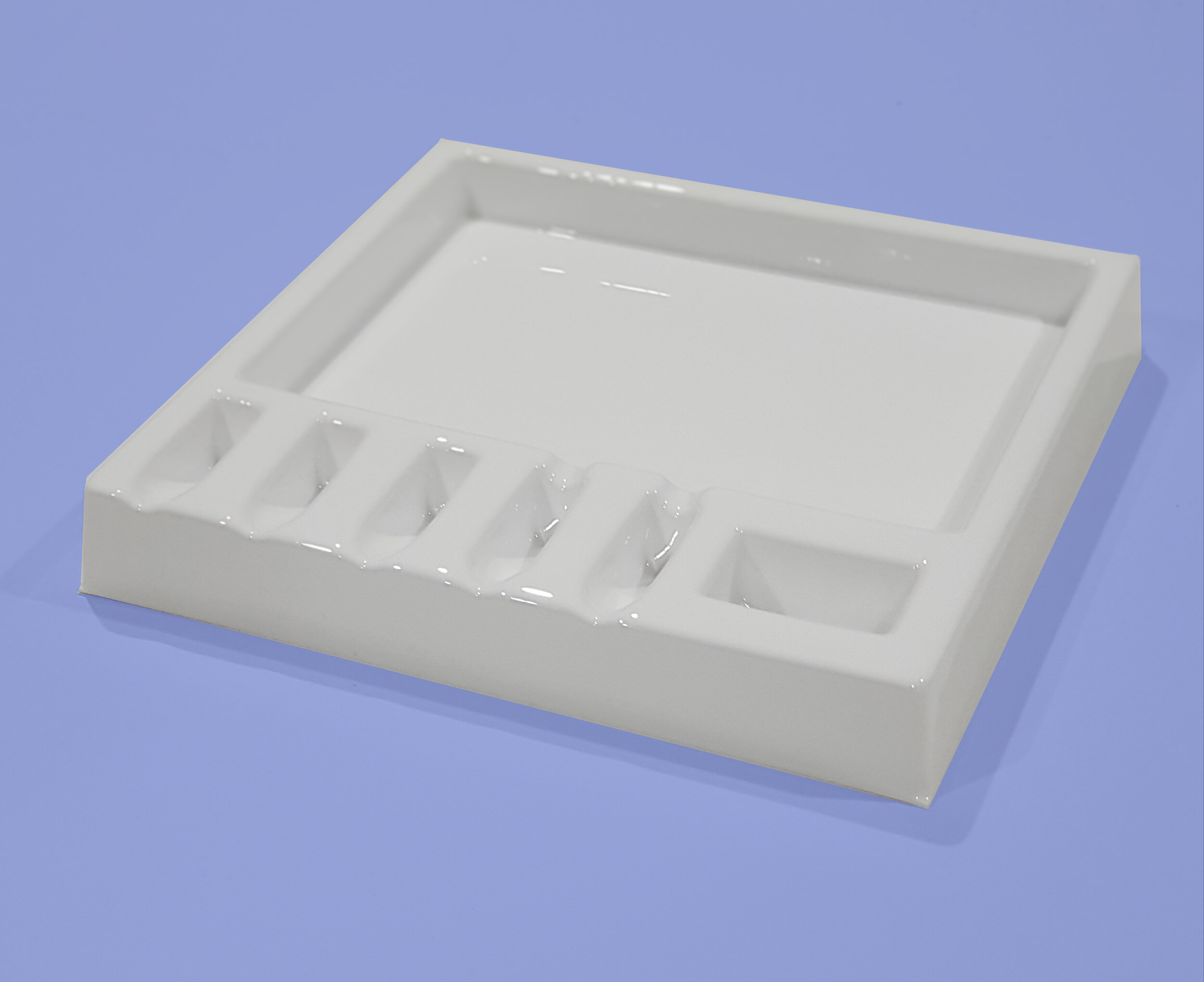

Component Moulding

Vacuum forming is the process of heating a plastic sheet to a forming temperature, stretching it onto a surface mould and forcing it against the mould by vacuum.

Popform provides support to businesses that require vacuum formed plastic components. Products range from thin gauge plastic packaging and inserts to heavy duty industrial mouldings. Vacuum Forming presents an opportunity, with relatively low set up costs, to customise products to your individual specifications.

We supply ongoing products for customers where batch quantities are required on a weekly or monthly consistent schedule. We create and store tooling and raw materials for customers so products can be vacuum formed as required.

CNC trimming provides the opportunity to finish moulded parts with complex cut outs or simple holes to aid in the assembly of parts for the end user.

A wide range of thermoplastics are available to suit your specific needs. Plastics that offer flame retardancy, high impact resistance, UV stabilisers, anti-static or glass like clarity are easily moulded by the vacforming process.

Typical components moulded by our process are external fan housings, case/box inserts, covers, automotive components, electrical components and tote boxes and inserts.